Profile Cutting & Splicing

In addition to our Extrusion capabilities, we have the ability to cut, form, and splice any extrusion that we produce to your specific requirements.

Profile Cutting

At Ames Rubber Manufacturing, We have a variety of choices for cutting profiles to suit your unique needs and tolerances.

Rotary Knife Cutting of rubber profiles can be achieved in-line with certain compounds, but is normally done after cure. This is a fast, economical way to cut profiles and tubing that have less stringent tolerances.

Guillotine Cutting of rubber profiles is used particularly with thicker cross sectional profiles such as bumper strips or larger custom profiles.

Radial Saw Cutting is used for particularly large or extremely thick extruded rubber profiles.

Reciprocal Blade Cutting is used for smaller cross sectional profiles with moderate to good tolerances.

Die Cutting is used for punching, notching or cutting thinner profiles.

Forming

We can form extruded rubber to conform to the geometric requirements of the finished part prior to curing the extrusion. This can help to relieve stress and flex in corners and more easily conform to the geometric requirements for sealing applications, such as automotive window seals.

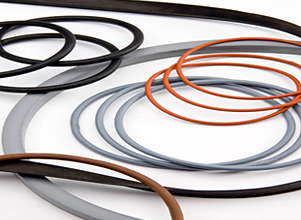

Splicing of Extrusion

In many cases, running the extrusion is only the first step in our customer’s requirements. Splicing is used when an application requires a continuous seal such as an O-ring or flange seal. When determining a spliced seal, the key considerations are physical integrity of the joint.

Features and advantages of spliced extrusions:

- Hollow cross-sections are excellent replacements for foam or sponge gaskets, offering superior compression set resistance.

- Used in interference-fit designs with asymmetrical solid or hollow cross-sections for ease of assembly in seal grooves without adhesives or mechanical retainers.

- A low-cost option for static face or radial face seal O-rings over 2.500″ I.D.

- Can be used in non-standard grooves.

Hot vulcanized splicing is considered the industry standard and is the best splice for most applications. The adhesive used is polymer based and when applied in a hot splicing press, vulcanizes the seal to itself, creating a seamless, leak free seal.

Hot vulcanizing offers:

- Superior hot vulcanization capability for high bond integrity

- Retains many of the properties of the seal itself based on type of adhesive utilized

- Reasonable strength

- More cosmetic splice than a cold splice

- Slower to splice than cold vulcanized splicing.

- Separate splicing molds are required

Cold vulcanized splicing is simply a matter of gluing two or more pieces of an extrusion together using quick-setting glue such as cyanoacrylate or super glue. Generally, cold splicing is less expensive depending on the complexity of the cross section and design of the seal.

Cold Vulcanizing offers:

- Faster production than hot vulcanized splicing for lower costs

- No tooling required for most profiles and materials

- Cold bonding is used where less bond integrity is needed

- Usually brittle and less cosmetically appealing

- RTV (room temperature vulcanization) Splicing is used for silicone and organic elastomers where heat vulcanization is not practical.

Sealing Solutions

Precision extruded and spliced products offer an ideal, cost-effective sealing solution for many applications.

These include:

- Low-closure force seals

- Large diameter profiles that cannot be molded

- Large diameter sealing areas where spliced rings are more cost effective than molding

- Hollow cross-section cord or requirements for non-standard O-rings and other extruded profiles with an inside diameter larger than 2.500 inches.

- Complex formed seals

- Tank O-rings

- Lens Gaskets

- Automotive Window Seals

- Your custom sealing applications