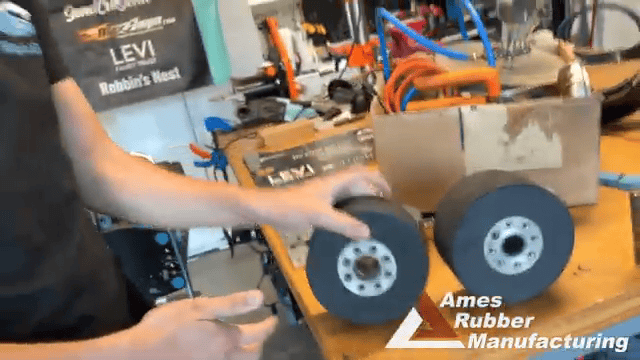

Custom Wheels for Robotics

Over the years, Ames Rubber Manufacturing has worked on many interesting and unconventional projects. Helping in Team Riptide’s quest to capture the elusive “Golden Bolt” on BattleBots was one of our most unique projects to date.

We were given drawings for a new and improved wheel to provide superior traction and resilience to abrasion and the attacks of rival robots during competition. The urethane wheels that the team had been using were deemed inadequate to withstand the rigors of robot combat.

We developed a compound that ensured that the wheels would not only comply with the competition’s mandated requirements, but also operate in a superior manner, formulated to withstand the high linear torque and traction forces produced by Riptide during competition.

After several iterations and revisions of the initial drawings, we produced a custom single cavity mold. This mold was used to compression mold the wheels, vulcanizing the compound to the hubs provided by Riptide. After prepping the inserts and molding the rubber to the hubs, the wheels were ground and finished to Team Riptide’s proprietary specifications.

This project showcases our capability to combine multiple manufacturing stages including insert preparation, compounding, compression molding, and finishing of custom rubber components to critical specifications. To learn more about our work with custom molded rubber parts, please contact us or refer to the table below.

Custom Wheels for Robotics Project Highlights

| Project Name | Molded Robotic Wheel for Team Riptide | |

| Project Description | Created tooling and developed a rubber compound used to produce rubber wheels for combat robotics | |

| Capabilities Applied/Processes | Primary: Compression Molding | Secondary: Mill Mixing & Compounding Custom Grinding |

| Equipment Used to Manufacture Part 40" Rubber Mills | 40" Rubber Mills 400 Ton Stewart Bolling 4 post Hydraulic Press with 24” X 24” platens. | |

| Overall Part Dimensions | Proprietary. Produced to conform to the requirements of the drawing | |

| Tightest Tolerances | Specified Radius and Tapers to fit allotted space and follow contours of the inserts. | |

| Material Used | Proprietary Rubber compound. | |

| Material Color | Black. | |

| Industry for Use | Robotics. | |

| In Process Testing/Inspection Performed | Visual inspection for nicks and voids. Computer aided visual inspection for size. | |

| Volume | Low. | |

| Packaging | Custom – Boxed. | |

| Delivery/Turnaround Time | Wheels were produced within a short period of time to meet the deadline of the competition. | |

| Delivery Location | Local. | |

| Standards Met | Customer specifications within the standards and rules of the competition. | |