Mold & Die Making

Proactive design for better solutions.

Could a minor change in the way a mold is made make manufacturing of your parts more efficient? Can a slight modification or adjustment to a current extrusion die save you time and money? At Ames Rubber Manufacturing, our years of production experience help us to proactively optimize your mold, or die, making the process faster and more efficient, creating better parts at a lower cost.

Mold making is both a science and an art.

Machinists that claim to be “all-purpose” seldom have the expertise to provide the best solutions to your specific needs. Even companies that advertise expertise in both plastic and rubber often lack a depth of knowledge in the intricacies of material shrinkage, die swell, and flash control.

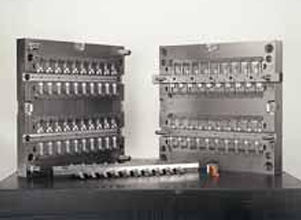

Mold Making

Ames Rubber Manufacturing has in-house mold making and repair capabilities to create tooling for your rubber molding needs. We also partner with a number of top quality mold makers that specialize in different types of compression, transfer and injection molds and fixtures, as well as Wire EDM for extrusion dies, and CNC Laser cut die boards for steel rule dies, ensuring that all tooling will be made to your strict specifications at a competitive price.

- Single Cavity Molds

- Multiple Cavity Molds

- Compression Molds

- Transfer Molds

- Liquid Injection Molds (LIM)

- Low Flash Molds

- Splicing Molds

- Extrusion Dies

- Steel Rule Dies

- Precision Tolerances

Extrusion Dies

Our in-house machining capabilities give us the ability to create custom die profiles from scratch to meet your needs and or to quickly fine-tune existing extrusion dies to your exacting specifications.

There is no tooling charge for most cord or tubing sizes!

- Cord

- Tubing

- “U” Channels

- “D” seals

- Half Round

- “P” Seals

- “e” Channels

- Bulb & Channels

- Tadpole Seals

- Glazing Seals

- Wing Bumpers

- Squares & Rectangles

- Bumpers

- “C” Channels

- “L” Seals

- Bulb & T Seals

- “T” Seals

- “H” Channels

- Round Channels

- Grip Seals

Custom Machine Shop Services

If you need more than just rubber parts, Ames Rubber Manufacturing can produce the inserts or rollers that your part will be molded or bonded to. We can also create extrusion forms to cure our extrusion, formed to your required shape, such as in automotive window seals.

- Rollers

- Inserts

- Washers

- Fittings

- Fasteners

- Forms

- Fixtures

- Gears

- Tooling

- Templates

- Production Jigs

Mold Prototyping

For the best results in mold prototyping, we believe that a steel tool that is close to the expected finished product is best. Turn-around times for this option depend on the complexity of the part, but generally are no more than four weeks. In some cases, Aluminum tooling is also available for quick prototypes and very low production runs, but the extreme pressures used in the molding process may destroy this type of tooling before production decisions can be made.

Moving Existing Tooling

If you have existing tooling to produce your rubber product, but are not satisfied with your current vendor/supplier, Ames Rubber Manufacturing can help. We have assisted a number of our customers in moving their existing tooling to us, both quickly and with minimal interruption to our customer’s part supply and subsequent production cycle. We have production facilities in both the Eastern & Western United States so we can manufacture your product closer to your location when possible, saving on shipping costs and travel time.

We inspect incoming tooling prior to setting up for production to catch any problems that might affect quality or the safety of our operators. At Ames Rubber Manufacturing, your tooling will be treated with the utmost care, both during manufacture as well as in storage. This attention to detail ensures that your tools will be able to produce quality, in tolerance parts for a longer period before any rework is required.

Materials to Match your Tooling

Depending on the material specification and current source, we can usually continue to purchase and utilize the exact same material from the exact same source as your current supplier. If that is not possible, we have hundreds of polymer formulations on hand, and can provide standard compounds to meet your print or as requested. If your current vendor/supplier is controlling the raw material needed, Ames Rubber Manufacturing and its raw material partners can quickly develop a material that meets the required specifications. If the part has no documented specifications, we can help develop an ASTM specification to meet the given environment and application of the product.