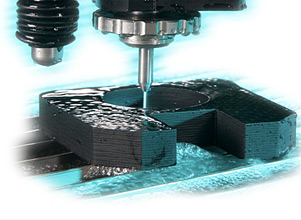

Waterjet Cutting

Waterjet cuts are made with an ultra-high pressure stream of either water, or garnet and water. The stream is computer numerically controlled (CNC) to precision cut almost any sheet rubber material that we stock.

While it has a longer cycle time and is subsequently more costly than standard die cutting, it is a proven way to provide complex parts when they are too thick for class A hardened tooling or standard steel rule dies, or when molded tooling is cost prohibitive for short runs.

Advantages:

- Cuts are very accurate due to computer control.

- It can cut complex parts when material thickness is prohibitive for other die cutting methods.

- Excellent for cutting high quality parts without costly cutting dies.

- The Waterjet cutting process is able to cut materials like laminates, phenolic, composites and most metals that were previously “unmachinable”. These cuts are made without fracturing, chipping or thermal stress compared to laser cutting.

- Material yield is maximized by cutting along common edges, reducing waste.

- Irregular parts can also be computer formatted to maximize material yield.

Materials

In addition to any sheet rubber that we stock, we offer Waterjet cutting services for these materials as well:

- Aluminum

- Ceramics

- Composites

- Glass

- Kevlar®

- Laminates

- Marble

- Phenolic

- Plastics

- Steel

- Tile

- Titanium